The sensor module for modern precision measurement

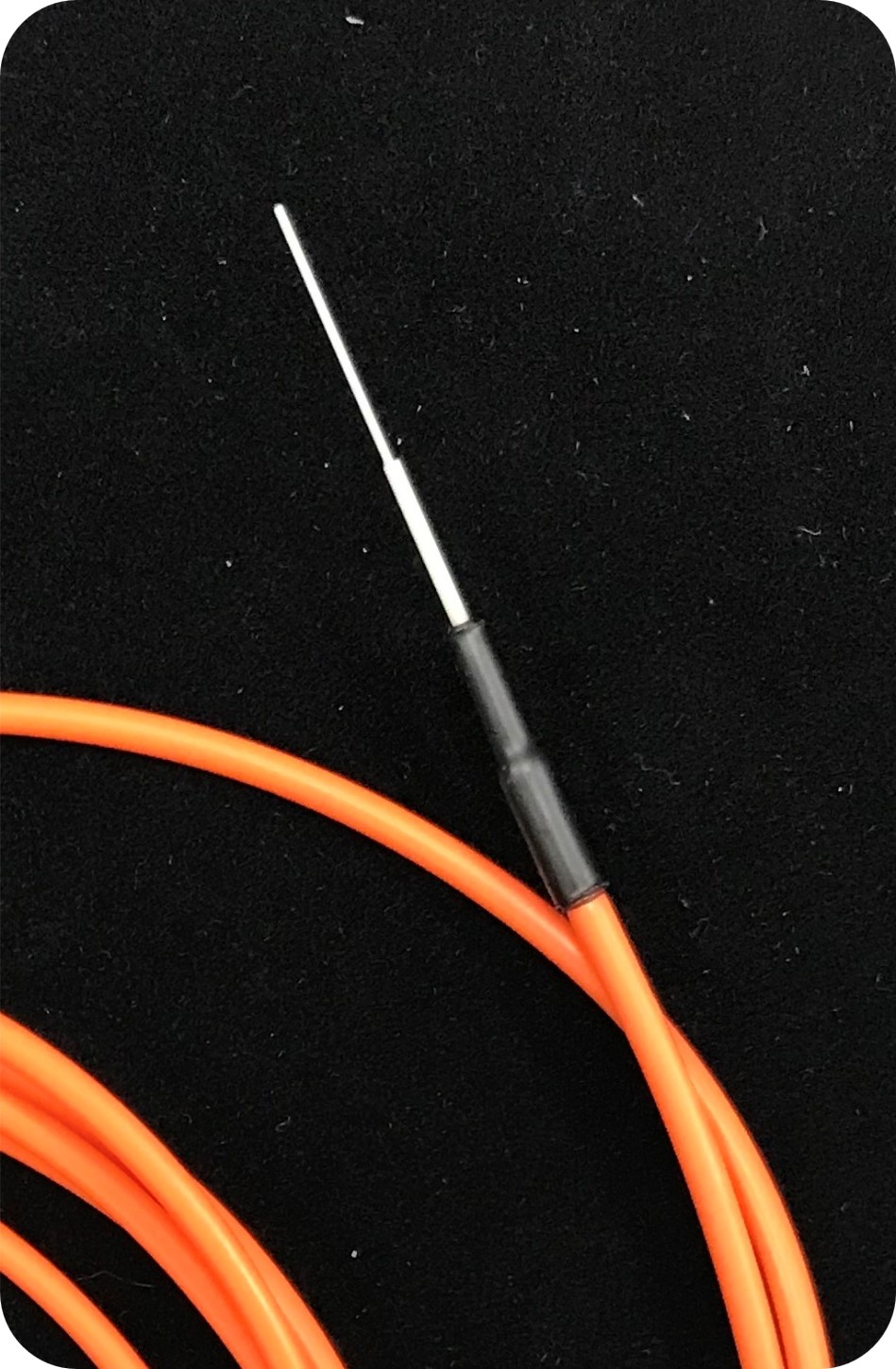

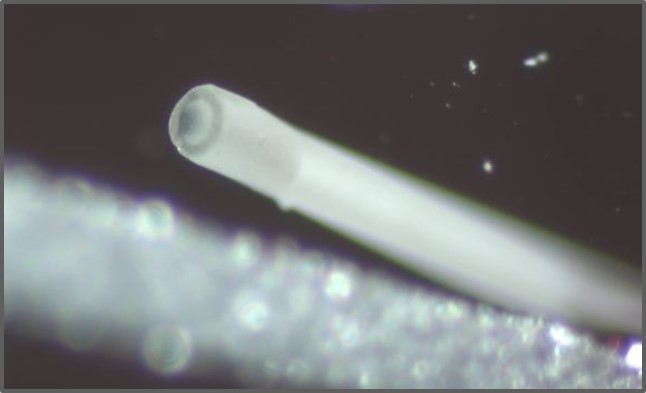

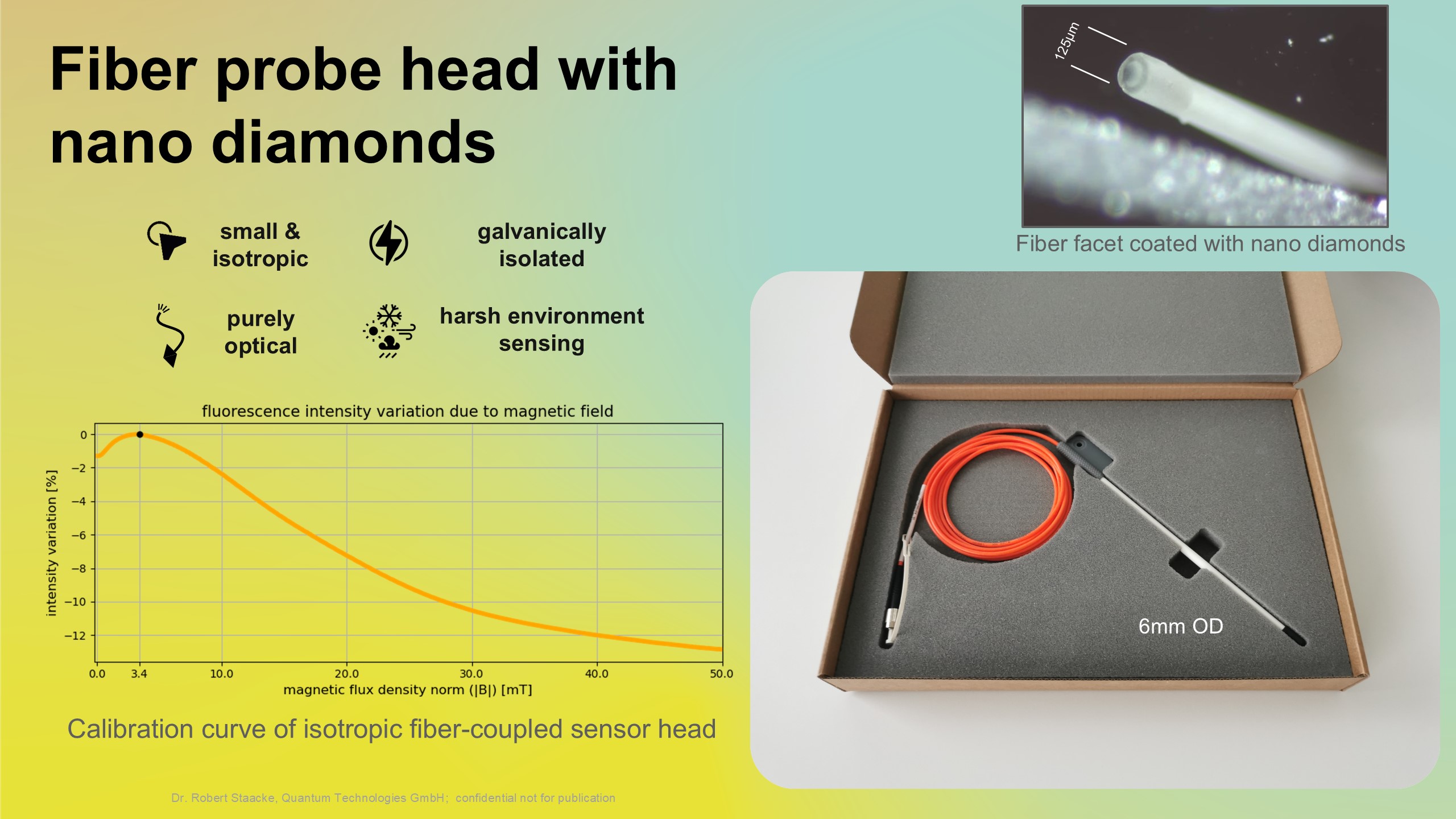

Our NV sensor measurement system uses a variety of diamonds with NV centers embedded in a transparent, hardened carrier material. Via optical fibers, the sensor element can be flexibly integrated into a wide range of environments.

- Fully optical & microwave-free: No metallic or galvanic coupling required, ensuring maximum safety at high voltages and full EMC robustness.

- Isotropic and pinpoint measurement: The arrangement and orientation of the NV diamonds enable reliable, direction-independent (scalar) magnetic field measurement, even in hard-to-reach locations such as the air gap of electric motors.

- Temperature- and chemical-resistant: Mechanical housing made of ceramic or glass allows permanent operation between −100 °C and +250 °C; also ideal for aggressive industrial environments.

- Measurement principle: Optical pumping and readout of the fluorescence of the NV centers through the optical fiber – sensitive to magnetic field strength without interference from the sensor element itself.

Typical fields of application:

- Industrial motor and generator monitoring: Precise detection of the magnetic field distribution in rotor/air gap for optimization and safety of drive systems.

- High voltage measurement: Complete galvanic isolation – no risk in high voltages or strong electromagnetic interference.

- Material testing and quality assurance: Non-destructive measurement even on small samples, thin layers, and complex geometries.

- Medical technology, research and development: Contactless measurements even on biological or sensitive samples.

Patented innovation:

The manufacturing process and sensor architecture are covered by our intellectual property rights – including all industrial production, assembly, and integration steps.

Discover the full potential of Quantum Technologies’ NV sensor measurement systems – the ideal solution for modern Industry 4.0, laboratory automation, and demanding high-voltage environments.