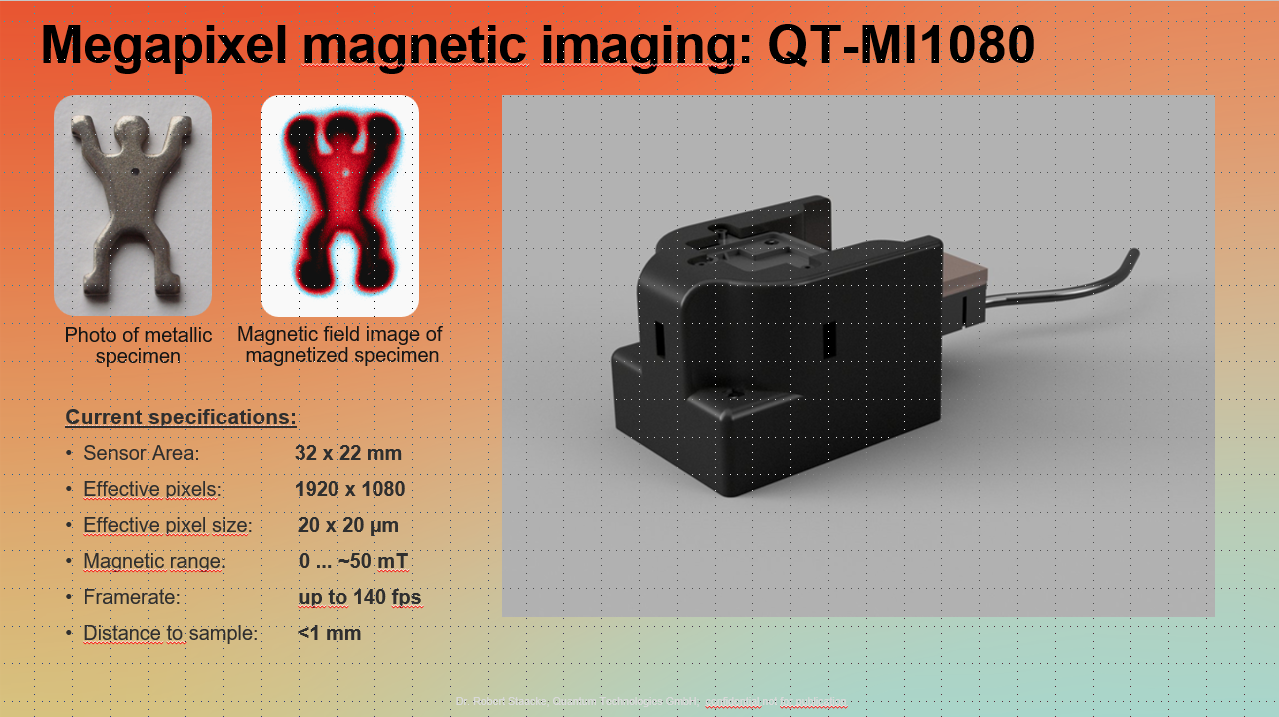

Technology & Demonstration

- The video shows an artificially produced iron plate with drill holes and thus demonstrates the detection of defects in ferromagnetic materials – completely non-destructive.

- The magnetic field camera works with NV diamonds: It measures changes in the magnetic field in high resolution (Full HD, up to 140 Hz frame rate).

- Defects such as cavities, cracks or inclusions immediately appear as local magnetic field anomalies in the image – fast, efficient quality inspection is possible.

- The sensor technology is 100% optical and microwave-free, fully galvanically isolated and also suitable for harsh industrial environments.

- Datasheet for the magnetic field camera (PDF)

Typical application areas

- Non-destructive material testing (NDT): Detecting cracks, blowholes, inclusions, welding defects or material variations – without damaging the material.

- Quality control & inline monitoring: Testing of motors, batteries, circuit boards and components directly during production.

- Research & development: Visualization of magnetization processes, material studies, detection of hidden structures.

- Electronics and PCB testing: Analysis of short circuits, openings and defects on PCB/E-motors.

- Medical technology & life sciences: Imaging with iron-containing contrast agents or magnetic nanoparticles.

- Security & authentication: Detection and analysis of security features on documents or banknotes.

Further information & technical details in the documentation/datasheet.

Or contact us directly for consulting or test setups.

Or contact us directly for consulting or test setups.