It's here. The future of sensor technology. And surprise, surprise - it's barely bigger than a sugar cube. With the microwave-free quantum magnetometer, we have achieved a real breakthrough: Until recently, highly sensitive methods for measuring magnetic fields required very large setups, had high power consumption and used components that either suffered from self-heating or influenced the fields to be measured with eddy currents. These times are history. Our sensor solution is small, cooling-free, cost-effective and nanometer-long more precise than anything known so far - simply sensortal!

Departure! Beyond the limits of the measurable to the quantum of unlimited possibilities: Physical quantities such as temperature, speed, electric and magnetic fields as well as positions are determined here with an accuracy never before realised. In order to advance into this dimension, our quantum sensor is based on the highly complex laws and procedures of the aforementioned quantum technology. The special feature: the measuring method is designed in such a way that the sensor does not require the use of microwaves. This, its extreme detection sensitivity and the wide detection range predestine it for a variety of applications. In particular for those for which there have been no functional measurement solutions up to now. Mind you, "there were", because we are currently working at full speed together with the industrial company duotec is working on industrialising the quantum sensor and making it commercially viable.

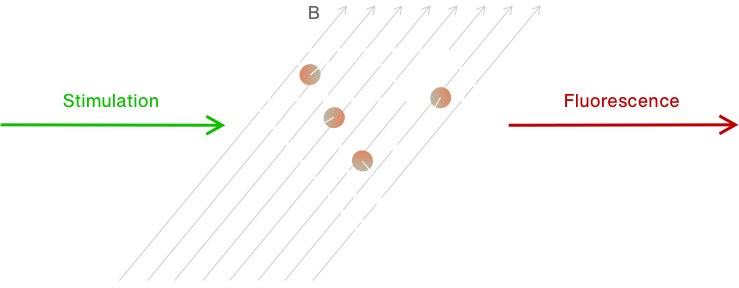

High-tech? Our sensor raises the bar - and this is how it works: The sensor system uses the magnetic field-dependent red fluorescence of high-density NV diamonds. The red fluorescence radiation is produced when the diamond is irradiated with green light. The sensor uses the magnetic field dependence of the spin states of the NV centers and the associated change in fluorescence intensity to measure the magnetic flux density - it's more complicated than it sounds.

The microwave-free, quantum-based magnetic field sensor has numerous advantages. One of them is not obvious, but in the housing: its compact format makes it super easy and inexpensive to set up. But beware, the dimensions are deceptive: small shell, strong core! Due to the fluorescent signal, our sensor reacts in less than 20 nanoseconds. Moreover, its surface has the maximum mechanical hardness (10). So it can be in direct contact with moving planes without any problems - or it can operate at enormous working distance, because it has that in spades, too. Inside it slumbers highly developed and, above all, unproblematic technology: thanks to scalar magnetometry, crystal alignment is not necessary. This means that sensor element alignment is also possible without any problems in later series production. Apart from that, neither sensor resets are necessary nor do hysteresis or memory effects occur. We put the icing on the cake with the legal usability, because the property rights are entirely ours.

The purely optical coupling of our sensor element is - literally - the measure of all things. The fact that no microwaves are used results in enormous possibilities and incomparable properties:

Whether different temperatures, ionising radiation or adverse environmental conditions: Almost nothing puts our quantum sensor in a measurable position. That is why it is particularly well suited for:

Together with the duotec GmbH, our competence partner and strategic investor, we are bringing the future of sensor technology into series production. A cooperation made to measure: duotec not only has the necessary know-how in the industrialisation of products, but also brings over thirty years of experience in the production and development of electronic assemblies and sensors as an EMS and E²MS service provider. Together, therefore, we form the perfect unit to develop a sensor based on quantum technology that is commercially viable and puts everything that has gone before in the shade. An absolute win for our customers, as they move into new dimensions - physically as well as economically.

Quantum Technologies GmbH

Alte Messe 6

04013 Leipzig

info@quantumtechnologies.de